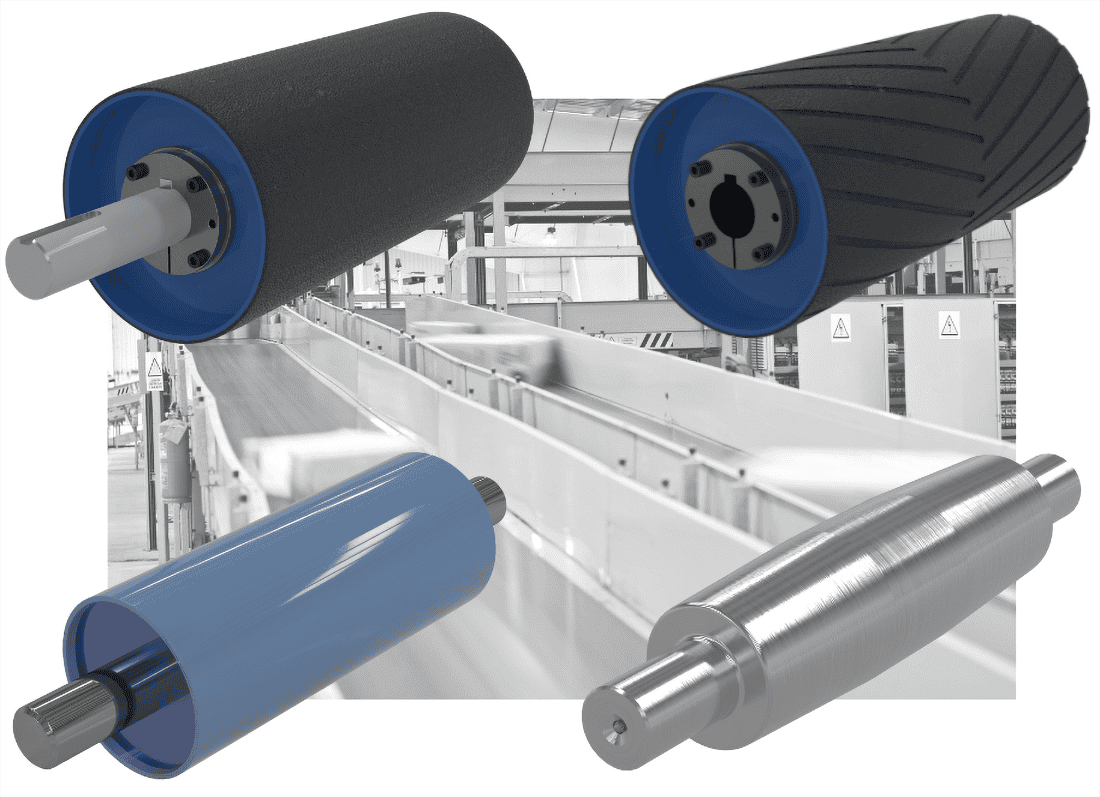

Conveyor Belt Pulleys

Woodsage conveyor pulleys are used to drive, guide and turn belted conveyor systems for material handling. Woodsage has been manufacturing industry leading conveyor components for more than 40 years, now, with an expanded offering for pulley products.

- Shortest lead times

- Best on-time delivery

- Made in USA

Conveyor pulleys from Woodsage are manufactured to your exact specification, keeping your equipment on-line and running efficiently. Woodsage’s world-class manufacturing facility paired with our tenured engineering team gives us the ability to provide high-quality conveyor belt pulleys at industry best lead times.

We understand material handling conveyance and have optimized our capabilities to be come a premier conveyor pulley manufacturer with products that are delivered on time with the shortest lead times in the industry.

What are short lead times and on-time delivery

worth to your pulley project scheduling?

| CONVEYOR PULLEYS | PRODUCT SPECIFICATIONS |

|---|---|

| Lengths (Face Width): | Up to 60" - Standard, Edge Crown, Trapezoidal Crown |

| Diameters: | Up to 8" Non-lagged, 9" Lagged |

| Materials: | Carbon Steel, Aluminum (custom options upon request) |

| Lagging: | Polyurethane, Neoprene, Vulcanized Rubber |

| Shafting: | Carbon Steel 1018, 1045, TGP (custom options upon request) |

| Pulley Type: | Drum Pulleys: Fully Welded, XT and QD Bushings |

| Solid Pulleys: Up to 5" Standard, Edge Crown, Trapezoidal Crown | |

Understanding Conveyor Pulleys

There are several different types of pulleys used in conveyor belt systems, each with its own function to keep the system running smoothly.

Drive Pulleys (aka Head Pulleys)

- Driving the belt: In systems where the drive unit is in the head section, the belt conveyor head pulley is powered and is used as the driving pulley that turns the entire belt.

- Redirecting the belt: Conveyor head pulleys change the direction of the belt, typically 180 degrees, so the belt can return for another cycle.

- Providing tension: Drive pulleys are typically adjustable, allowing for tension to be placed on the conveyor belt. Proper belt tension is required to prevent slippage.

- Tracking the belt: A key role of belt conveyor drive pulleys is to keep the belt centered. Proper alignment prevents the belt from drifting or running off-track

Snub Pulleys

- Belt Traction: Snub pulleys are used to increase the wrap angle (belt wrap) around the driving pulley, improving belt traction and reducing belt tension. By reducing tension your belted conveyor system can be better optimized for less wear and tear.

- Belt Tracking: Snubbing pulleys can also be used to keep the conveyor belt centered and reduce belt wandering.

Idler Pulleys (aka Return Pulley or Return Roller)

- Belt Support: A conveyor idler pulley may also be called a return roller and is used to provide support for the conveyor belt. When positioned at intervals along the conveyor belt, return pulleys will prevent the belt from sagging which could cause misalignment or damage.

- Reducing Friction: By providing additional rolling surface area for the belt, idlers reduce the friction between the conveyor belt and the structure. This also reduces the power needed from drive pulleys to move the belt providing smoother overall operation of the equipment.

Bend pulleys

- Changing Direction: The main function of a conveyor bend pulley is changing the direction of the belt. These pulleys are typically used to make a 180-degree bend in the tail section of the conveyor belt near the take-up.

- Bend pulleys can be designed to accommodate different belt types such as flat, cleated or modular plastic belts helping to provide smooth belt travel around curves.

Tail Pulleys

- Belt Redirection: A conveyor tail pulley provides transition from the carrying run (moving materials) to the return run (belt traveling back to head pulley), usually through a 180-degree belt change in direction

- Belt Tension: Conveyor tail pulleys work together with the take-up section to maintain the correct amount of tension on the conveyor belt. Typically, a tail pulley can be adjusted to increase or decrease tension as needed.

- Belt Tracking: Similar to drive pulleys, tail pulleys help keep the conveyor belt aligned and properly centered to avoid misalignment and premature wear.

Take-up pulleys

- Belt Tensioning: The most important function of a take-up pulley is to apply or adjust tension on a conveyor belt. Having the correct amount of tension on the conveyor belt is required for efficient operation and prevents belt slip, sagging and premature wear.

- Taking-up Belt Stretch: Due to load tensions and prolonged usage, conveyor belts can stretch over their useful lifetime. Take-up pulleys can be adjusted to take up the stretch, preventing belts from becoming too loose.

- Accommodating Belt Installation / Removal: Conveyor take-up pulleys can be adjusted to create slack in the belt allowing for easier removal and installation of new conveyor belts during maintenance.

Conveyor belt systems rely on various types of pulleys to operate efficiently. Each pulley type plays a critical role in ensuring proper operation of the conveyor system while used in material handling systems.

Unlike other conveyor pulley suppliers, Woodsage provides a one stop shop for your conveyance component needs. High-quality conveyor pulleys, conveyor rollers, and custom precision fabricated tube products.

Our engineering and customer service teams are waiting to make your next project a reality - Reach out today!